CrusherChutes

Chutes Boxes Mining Material Handling Corrosion Engineering

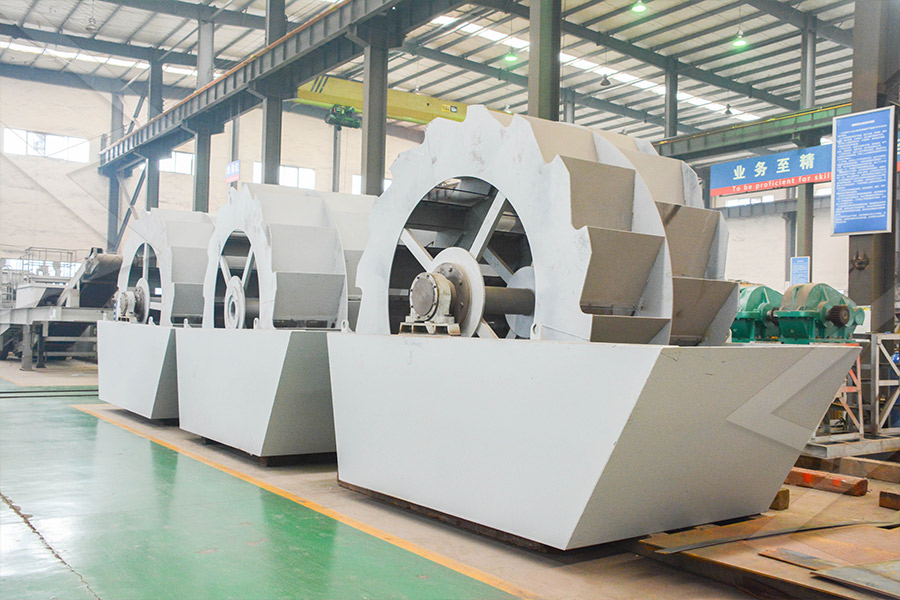

We build discharge chutes, crusher chutes, feed chutes, screen chutes, stacker chutes, and more Corrosion Engineering’s chute systems are designed to control material flow, designs, manufactures and supplies engineered and tailored chute solutions to your exact needs This includes lined hood and spoon style chutes as well as our Wearback™ Chutes

.jpg)

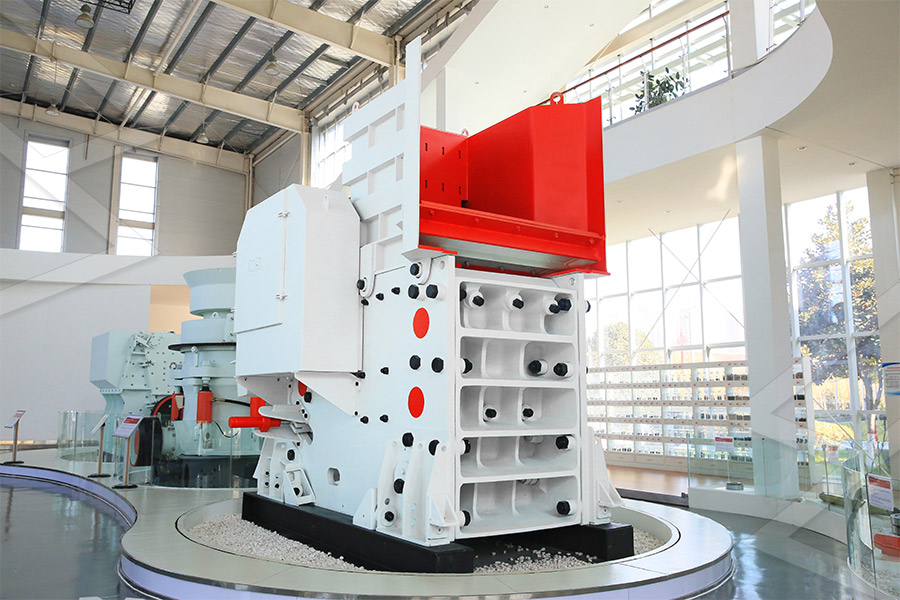

4: The feeding chute of the HPGR crusher in gray and the

The work is divided into three areas: physical modeling, control modeling, and circuit modeling Physical modeling deals with how to develop high fidelity unit models of After obtaining the best feed chute design by the simulation, the modified cylindrical feed chute was constructed and installed in one of the tertiary cone crushers (No 3) of the DEMbased design of feed chute to improve performance of cone crushers

Wear linings for crusher discharge vaults

For crusher discharge vaults, the Xlok system is our preferred solution It is a tough modular liner system designed to be accessed only from the inside of the chute Xlok Chute Liners designed manufactured by Makuri Technology to optimize the front end of hard rock mining Chute Liners, Rom Bins, Dump PocketsChute Liners designed manufactured by Makuri Technology

.jpg)

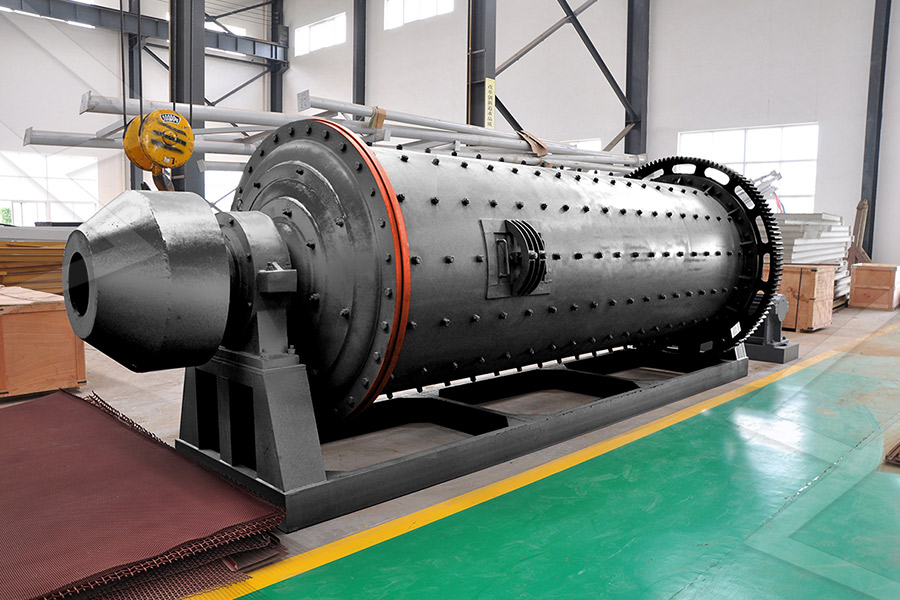

Crushing Circuit Chutes and Screens Wear Material

8 years ago Our crushing circuit contains primary crusher jaw , secondary cone crusher and tertiary cone crusher in which closed circuit with a double deck screen the ore is quartz Most of the price of Crusher Liner ranges from US $ 1 to $ 3500 per kg It's important to research and compare different models and features to find the best Crusher Liner for Crusher Liner MadeinChina

Fixed Plant Liners for Transfer Chutes/ Crusher Liners/ Sizing Screens

Product Description Fixed Plant Liners for Transfer Chutes/ Crusher Liners/ Sizing Screens The smooth overlay plate was manufactured using advanced fusion bond submerged arc Six crusher plant sites were selected based on their varying production capacity for the study Accordingly, selected sites were visited to carry out area noise and wholebody vibration surveys(PDF) Noise and Vibration Control in Crusher Plant Activities

roll crusher feed and discharge chutes instructions 2020md

Application of the roller crusher principle to processing corncobs showing spiral crushing and feeding rollsOne of theOne installation pro 1eatad between theia# Adjustable gates oa the discharge side of the rolls canCrusher Discharge Chute Drawing Jaw Crusher,ConeRoll crusher feed and discharge chutes lyrics youtube crusher users to replace worn parts or Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that direction of the arrows (black lines) It is critical that these are in the right direction or it may not work Use the wrench to rotate them as needed The Crushing Wheel Create Wiki Fandom

.jpg)

Powered Chutes Unofficial Stationeers Wiki

Description Used to transport items The Kit can be used to create 5 different variants, all of which require power and can connect to data ports Chute Digital Valve Right: Allows a certain number of items through, then closes until reopened either manually or via data network Chute Digital Valve Left: Allows a certain number of items Traditional crusher discharge chutes, vaults and octagonals are a challenge to protect with wear liners and can be even more difficult to maintain and repair They are often surrounded by structural concrete, which prevents access to the back side of the chute and excludes the use of traditional fastenersWear linings for crusher discharge vaults

Overcoming the challenges of blocked chute detection in

It is well recognized that transporting irregularshaped bulk solid materials over long or short distances presents a number of operational challenges Primary crusher crash boxes, conveyors, transfer lines, inlet/outlet chutes and inlet hoppers can all be prone to blocking, bridging or jamming, resulting in severe site problems These include:This is particularly pertinent in the design of protective coatings for crusher feed chutes, where the use of innovative, highdensity materials is essential to ensure structural integrity and longevityNumerical analysis of a protective coating for mining

Chutes Liners Archives Bulk Handling

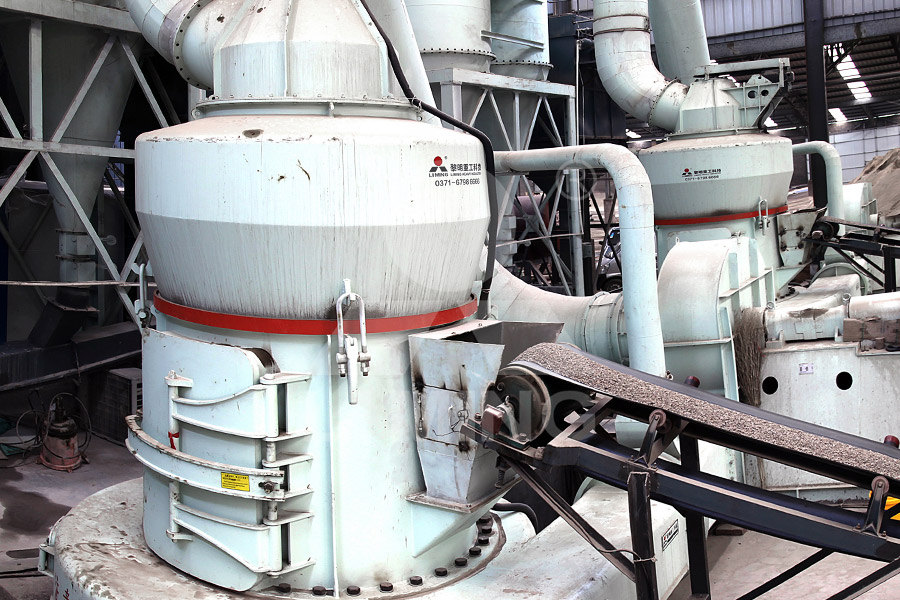

A Detailed Understanding of Chutes Channeling the flow of mined material is among the most onerous tasks on any mine, and Weba Chute Systems designs and manufactures its solutions to withstand these demanding applications The considerable wear on the components in a transfer point, however, requires constant monitoring and attentionLandscaping Chutes Ideal for: Light, flexible, and safe Quiet during use Equipped with safe and strong cable linking hardware CONTACT / REQUEST QUOTE BackPremier Equipment Chute Systems

OPPDry: Materials Handling Facilities Oil Sands Magazine

The roller teeth are covered with wearresistant caps These caps wear down and are periodically replaced Both the feed and discharge chutes are normally covered in wearresistant plates to minimize erosion As in the case of the main dump hopper, many crusher chutes have electric heating elements to prevent the oil sands from stickingCrushers Makuri Technology is able to supply a range of selected major machine parts to most commonly available crushers, with a level of quality and performance that meets or exceeds the OEM We use our international supply chain offices in 5 countries and 3rd party independent QA vendors globally to seek out and audit suppliers and parts on Crusher Parts The Makuri Group

.jpg)

Chute Design Essentials – How to Design and Implement Chutes

Published in bulk solids handling, Vol 35 (2015) No 6 Chutes are in use in almost every bulk solids handling plant Although everybody knows them, they are mostly overlooked, except for those cases where they cause extraattention and work due to malfunctioning Following you will find hints to prevent such incidents This paper attempts to give the 1 Spiral chutes application in Gold Processing Spiral chutes effectively separate valuable gold ore from other heavy minerals Its unique spiral design allows for a smooth and controlled material descent, ensuring high recovery rates and minimal waste This innovative device is particularly effective at handling finegrained materials, making Improving Mineral Processing Efficiency With Spiral Chutes

.jpg)

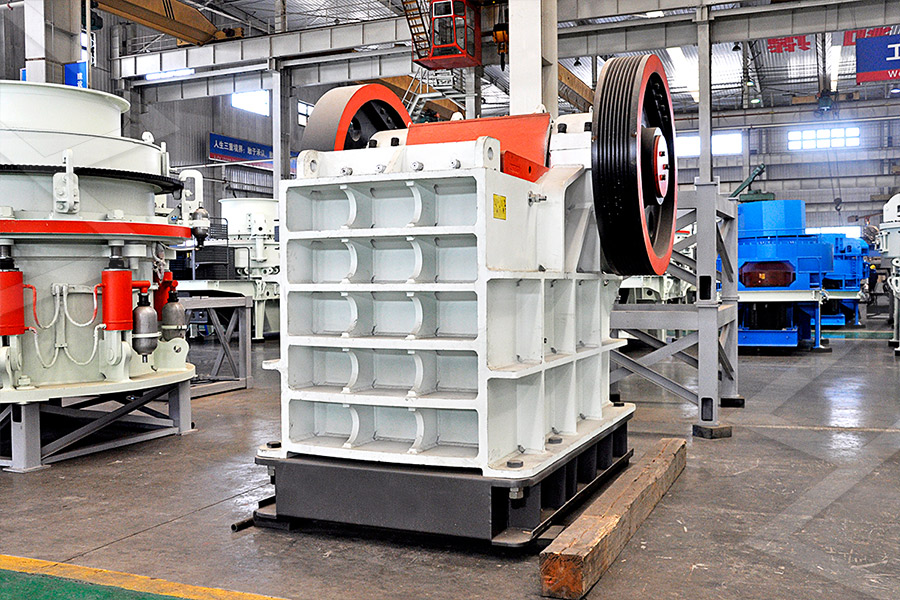

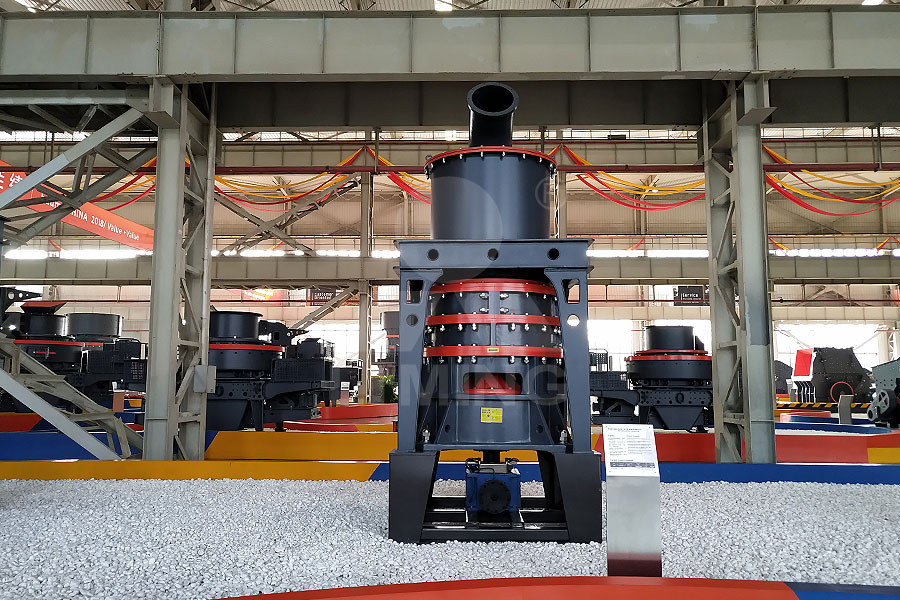

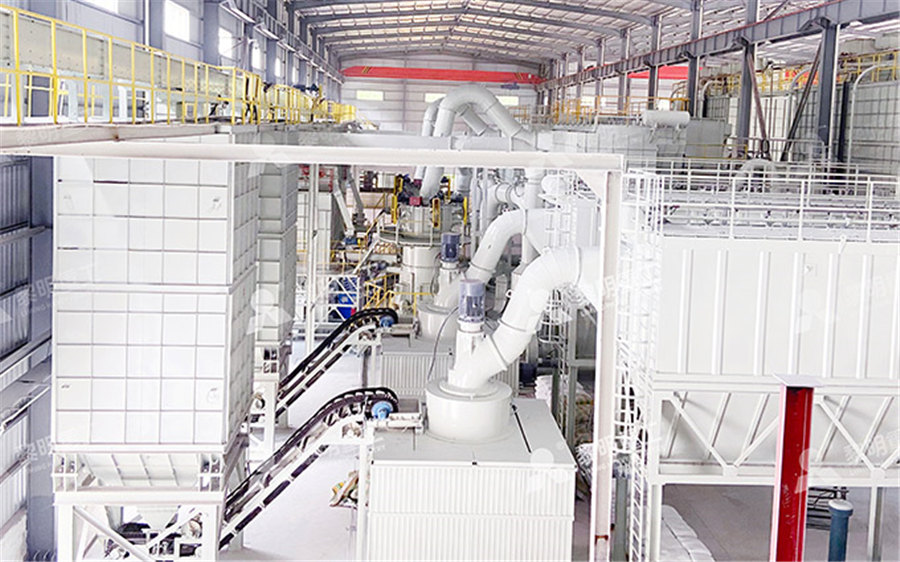

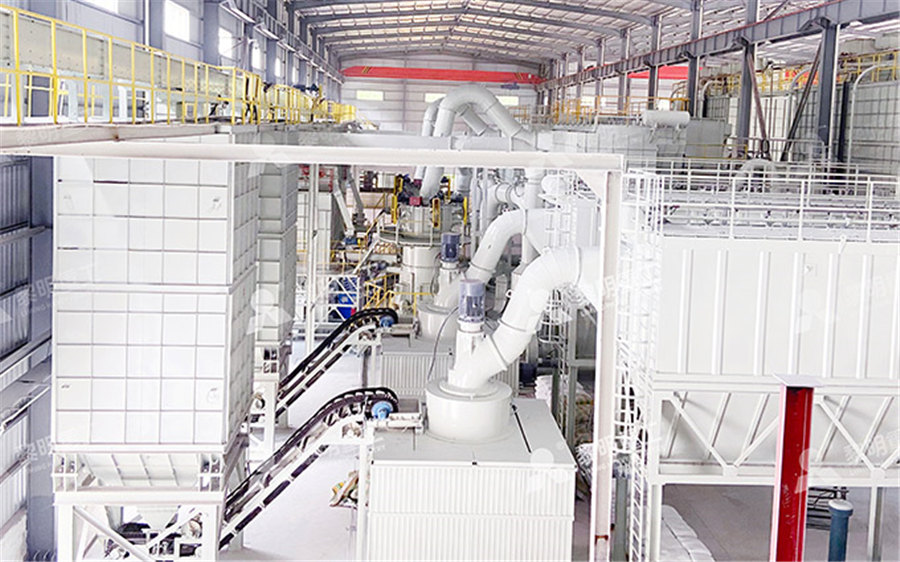

DEMbased design of feed chute to improve performance of cone crushers

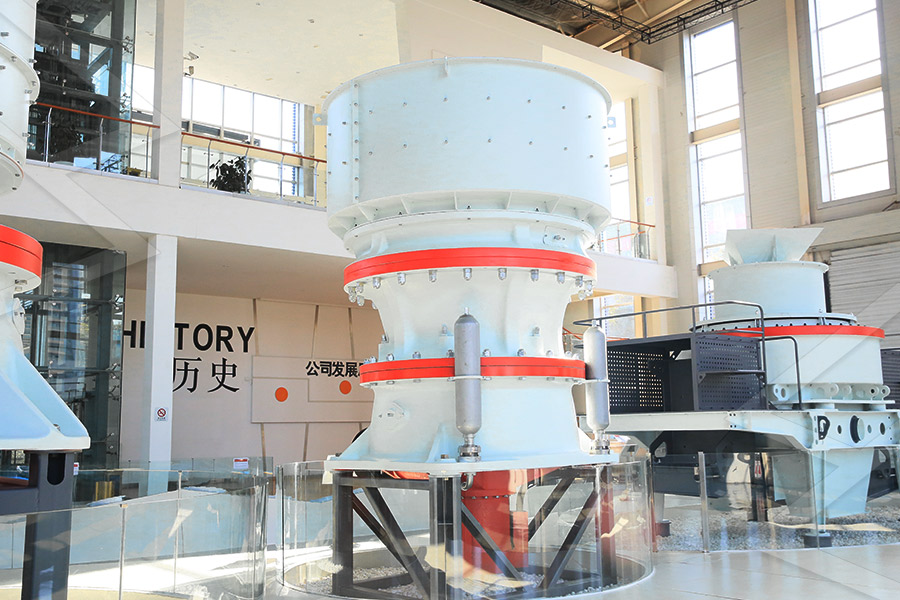

The effect of feed chute design on tertiary cone crusher performance at the Sarcheshmeh copper complex was studied by an inhouse developed DEM software called KMPC DEM © To simulate the overall crushing circuit, the multigeometry procedure by improving the routines of object files importing into the simulation environment was implemented in 4 500 chute installations Effective transfer of materials in chutes has become a pressing issue for all mines With the spotlight firmly on increasing productivity through more effective discharge of materials, coupled with minimising downtime and maintenance, solutions are critical to sustainability With more than 4 500 transfer chute installations throughout the 4 500 chute installations Bulk Handling

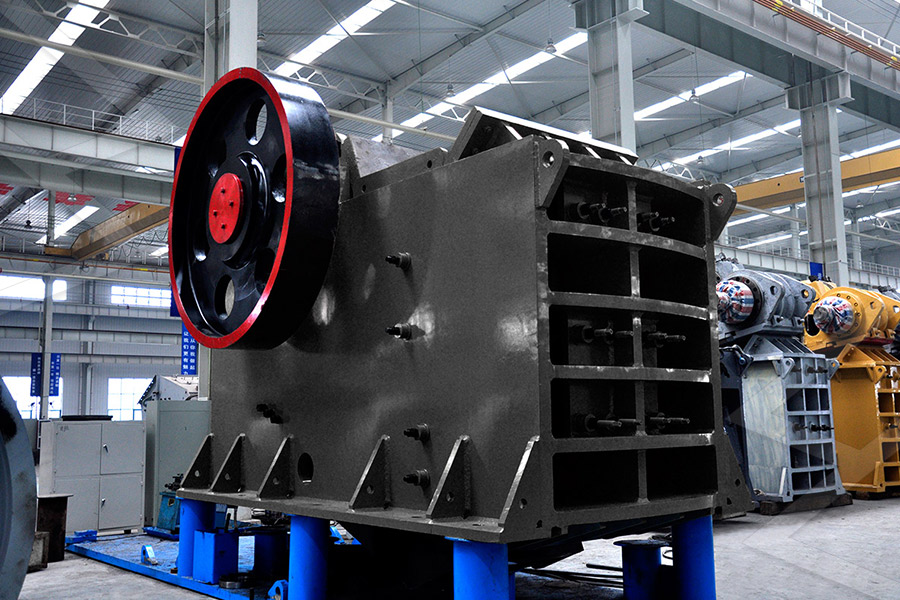

Crushing Plant Design and Layout Considerations

ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical design parameters as well as the consideration of ore characteristics, geographical location, climatic conditions, Explore the various types of crushers and their functionalities in our detailed guide Get insights on types of crushers for your next projectTypes of Crushers Explained: Everything You Need to Know

.jpg)

Chutes KVK Hydra Klov

Compare the KVK Hydra Klov professional hoof trimming chutes Find different hooftrimmer and farmer chutes used for trimming the claws of cows1 Introduction Liner life in stockpile reclaim chutes is critical to processing plant performance Stable stockpile levels are required to ensure stable mill operation, and shutdowns in this area can affect the entire plantMicrosoft Word Case Study Reclaim chute linersdocx

(PDF) Noise and Vibration Control in Crusher Plant Activities

Six crusher plant sites were selected based on their varying production capacity for the study Accordingly, selected sites were visited to carry out area noise and wholebody vibration surveysApplication of the roller crusher principle to processing corncobs showing spiral crushing and feeding rollsOne of theOne installation pro 1eatad between theia# Adjustable gates oa the discharge side of the rolls canCrusher Discharge Chute Drawing Jaw Crusher,ConeRoll crusher feed and discharge chutes lyrics youtube crusher users to replace worn parts or roll crusher feed and discharge chutes instructions 2020md

.jpg)

Crushing Wheel Create Wiki Fandom

Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that direction of the arrows (black lines) It is critical that these are in the right direction or it may not work Use the wrench to rotate them as needed The Description Used to transport items The Kit can be used to create 5 different variants, all of which require power and can connect to data ports Chute Digital Valve Right: Allows a certain number of items through, then closes until reopened either manually or via data network Chute Digital Valve Left: Allows a certain number of items Powered Chutes Unofficial Stationeers Wiki

.jpg)

Wear linings for crusher discharge vaults

Traditional crusher discharge chutes, vaults and octagonals are a challenge to protect with wear liners and can be even more difficult to maintain and repair They are often surrounded by structural concrete, which prevents access to the back side of the chute and excludes the use of traditional fastenersIt is well recognized that transporting irregularshaped bulk solid materials over long or short distances presents a number of operational challenges Primary crusher crash boxes, conveyors, transfer lines, inlet/outlet chutes and inlet hoppers can all be prone to blocking, bridging or jamming, resulting in severe site problems These include:Overcoming the challenges of blocked chute detection in

Numerical analysis of a protective coating for mining

This is particularly pertinent in the design of protective coatings for crusher feed chutes, where the use of innovative, highdensity materials is essential to ensure structural integrity and longevityA Detailed Understanding of Chutes Channeling the flow of mined material is among the most onerous tasks on any mine, and Weba Chute Systems designs and manufactures its solutions to withstand these demanding applications The considerable wear on the components in a transfer point, however, requires constant monitoring and attentionChutes Liners Archives Bulk Handling

Premier Equipment Chute Systems

Landscaping Chutes Ideal for: Light, flexible, and safe Quiet during use Equipped with safe and strong cable linking hardware CONTACT / REQUEST QUOTE Back